Fungal Alpha Amylase

Product Details:

- Medicine Type Enzyme preparation

- Purity 99% (Enzyme purity)

- Efficacy High enzymatic activity for starch hydrolysis

- Chemical Composition Alpha Amylase Enzyme from Aspergillus oryzae

- Best Before 24 months from manufacturing

- Strength High potency

- Effect Efficient starch breakdown, improved fermentation

- Click to View more

X

Fungal Alpha Amylase Product Specifications

- Enzyme preparation

- High enzymatic activity for starch hydrolysis

- 5 Kg, 10 Kg, 25 Kg

- 99% (Enzyme purity)

- Alpha Amylase Enzyme from Aspergillus oryzae

- Sorbitol, Sodium Chloride, Calcium Chloride

- Fungal Derived Alpha Amylase

- Store in cool, dry place, away from direct sunlight

- HDPE Drum / Bags

- 24 months from manufacturing

- High potency

- As recommended for industrial or baking processes

- Efficient starch breakdown, improved fermentation

- Mix with substrate as per suggested concentration

- Neutral

- 2 Years

- Powder

- Enzymatic conversion of starches to sugars

- Optimal activity at pH 5.06.0

- Optimal at 50C 60C

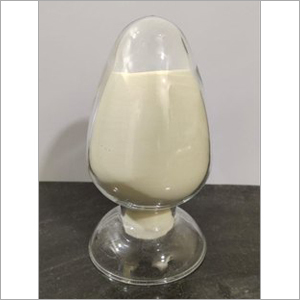

- Off-white to light brown powder

- Soluble in water

- 20002500 IU/g

- Characteristic, mild

- Max 8%

- Baking, brewing, distilleries, textiles, detergents

Product Description

Fungal Alpha Amylase

Fungal Alpha Amylase is a powdered formulation which is used as a food grade enzyme for the starch sugar. It is prepared via the fermentation and extraction of the Aspergillus oryzal var. This free flowing substance is fast in action and available in acidic, neutral as well as alkaline forms. It has good heat resistance that makes it suitable for the industrial as well as agricultural applications. Buyers can get this top quality substances in large volumes at a reasonable price.

High Enzyme Efficacy for Industrial Applications

Engineered for robust performance, Fungal Alpha Amylase exhibits high enzymatic activity, ensuring rapid starch breakdown and improved fermentation across baking, brewing, and distillery processes. Its consistent efficacy enhances dough handling, sugar yield, and overall product quality in these sectors.

Product Formulation and Safety

Supplied as a fine, off-white to light brown powder, the enzyme preparation contains fungal-derived alpha amylase with sorbitol, sodium chloride, and calcium chloride as sub-ingredients. It maintains a neutral flavor and characteristic mild odor, making it suitable for both food and non-food industry requirements.

Optimal Usage and Storage Guidelines

To maintain potency and extend shelf life, Fungal Alpha Amylase should be stored in a cool, dry place away from direct sunlight. Dosage should adhere strictly to recommended concentrations for each industrial application, ensuring consistent performance without compromising quality.

FAQs of Fungal Alpha Amylase:

Q: How is Fungal Alpha Amylase used in industrial applications?

A: Fungal Alpha Amylase is incorporated by mixing its powder form with substrates such as flour or grains at concentrations recommended for specific processes. It facilitates enzymatic conversion of starches to sugars in baking, brewing, distilleries, and detergent manufacturing.Q: What are the benefits of using Fungal Alpha Amylase in baking and brewing?

A: The enzymes high potency enables efficient starch hydrolysis, resulting in improved dough texture, better fermentation, and an increased yield of fermentable sugars. This leads to enhanced product consistency and quality in both baking and brewing industries.Q: When should Fungal Alpha Amylase be added during processing?

A: It should be introduced during the initial mixing stage of dough or mash preparation, ensuring uniform enzyme distribution and optimal biochemical conversion as the temperature and pH reach their recommended ranges for activity.Q: Where should Fungal Alpha Amylase be stored for best stability?

A: For optimum shelf life and preservation of enzymatic activity, store the powder in a cool, dry location, away from direct sunlight, and keep containers tightly sealed. HDPE drums or bags protect product integrity during storage and transport.Q: What is the recommended dosage for Fungal Alpha Amylase?

A: Dosage varies based on application and substrate; adhere to manufacturer guidelines for concentration to achieve desired enzymatic activity and process results, whether in baking, brewing, or other industrial uses.Q: How does Fungal Alpha Amylase improve fermentation efficiency?

A: Through rapid starch breakdown at optimal temperature and pH conditions, this enzyme increases the amount of fermentable sugars available, leading to enhanced fermentation rates and higher yields in both brewing and distillation.Q: What ingredients and chemical composition does Fungal Alpha Amylase contain?

A: It consists of fungal-derived alpha amylase enzyme from Aspergillus oryzae, with sorbitol, sodium chloride, and calcium chloride as stabilizers, ensuring enzyme purity at 99% and reliable function in diverse applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free